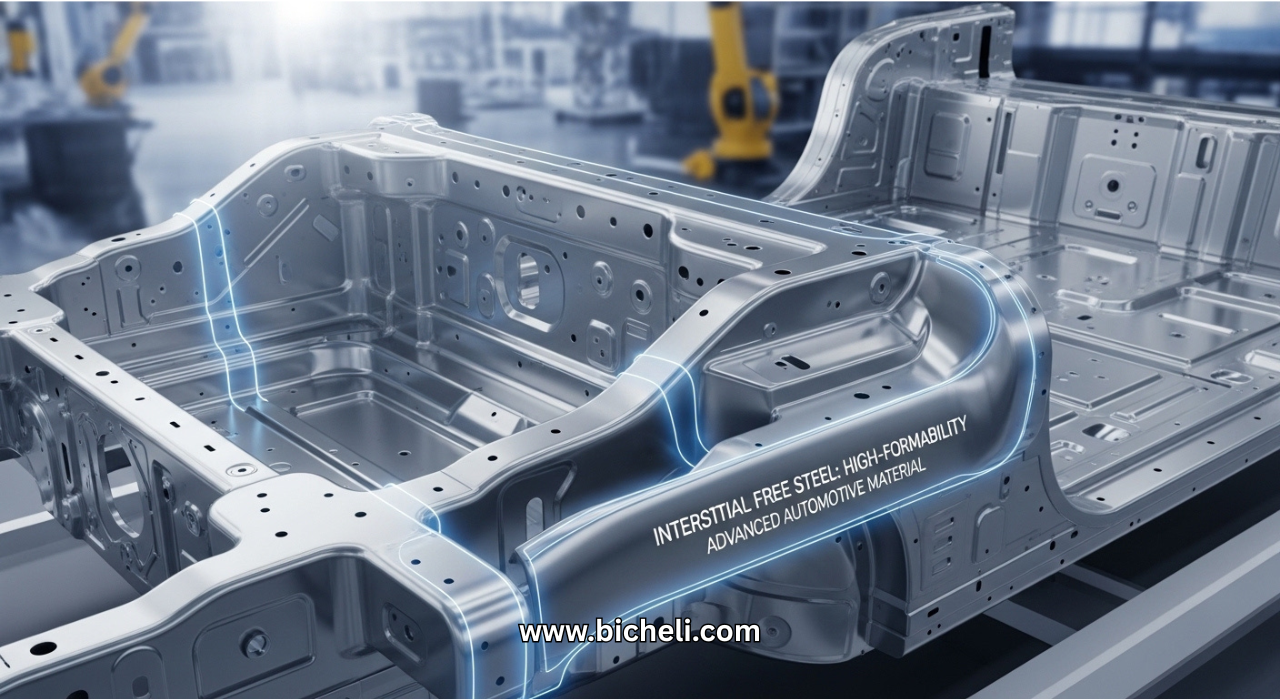

Interstitial Free (IF) steel has emerged as a cornerstone material in modern automotive manufacturing. Known for its exceptional formability and deep-drawability, IF steel offers unique advantages that traditional carbon steels cannot match. From ultra-low carbon content to the strategic use of alloying elements, this steel grade has transformed how engineers design lightweight, durable, and complex vehicle components.

What is Interstitial Free Steel?

Interstitial Free steel is a type of low-carbon steel characterized by extremely low levels of carbon and nitrogen—often measured in parts per million (ppm). These interstitial atoms, if left unbound, can significantly reduce ductility. To prevent this, elements like titanium or niobium are added during the steelmaking process. These alloying elements form stable compounds with carbon and nitrogen, effectively “locking” them in place.

The result is a steel with a fully ferritic microstructure that offers high uniform elongation and unmatched formability. Unlike conventional steels, which may deform unevenly or spring back during forming, this material maintains a smooth, predictable behavior during complex shaping operations.

The History and Development of Interstitial Free Steel

Interstitial Free steel was first developed in the 1980s in response to the automotive industry’s growing demand for lightweight, easily formable materials. Car manufacturers faced challenges in creating panels with intricate curves and sharp bends without causing cracks or surface defects. Traditional low-carbon steels were prone to these issues, limiting design possibilities.

By introducing titanium or niobium to bind residual carbon and nitrogen, metallurgists created a steel that retained its soft, ductile properties across large sheets. Over the decades, its adoption expanded beyond automotive applications to include appliances, furniture, and other industries requiring deep-draw steel.

Key Properties of Interstitial Free Steel

The unique characteristics of IF steel make it a preferred material for a wide range of applications:

-

Ultra-Low Carbon and Nitrogen Levels – With carbon and nitrogen content measured in ppm, IF steel has minimal interstitial atoms, leading to reduced internal stresses and enhanced ductility.

-

High Formability – Its ferritic structure allows the material to be drawn into complex shapes without tearing, making it ideal for deep-drawn automotive panels.

-

Softness and Flexibility – IF steel is softer than traditional low-carbon steels, allowing for easier stamping and bending processes.

-

Surface Quality – The reduced risk of surface defects ensures a smooth finish, which is crucial for visible components like car exteriors.

-

Predictable Behavior in Manufacturing – Uniform mechanical properties reduce the risk of unpredictable deformation during forming operations.

Applications in the Automotive Industry

One of the most significant uses of this steel is in automotive body panels. The combination of softness, ductility, and deep-drawability enables engineers to design panels with intricate curves, sharp bends, and lightweight structures without compromising strength.

Key applications include:

-

Exterior Panels: Doors, hoods, and fenders benefit from the smooth surface finish and formability.

-

Structural Components: While primarily used for visible panels, IF steel is sometimes integrated into lightweight structural parts.

-

Interior Elements: Dashboard components and trim elements also leverage its ease of forming.

The automotive industry’s adoption of this material has helped reduce overall vehicle weight, improve fuel efficiency, and enhance design flexibility, all while maintaining safety and durability standards.

Comparison with Other Steel Grades

To understand the advantages of IF steel, it is useful to compare it with traditional low-carbon and high-strength steels:

| Feature | Conventional Low-Carbon Steel | High-Strength Steel | Interstitial Free Steel |

|---|---|---|---|

| Carbon Content | 0.05–0.2% | 0.2–0.3% | <0.005% |

| Ductility | Moderate | Low to Moderate | Very High |

| Formability | Limited | Poor | Excellent |

| Surface Quality | Moderate | Variable | Superior |

| Springback | Noticeable | High | Minimal |

As the table shows, the ultra-low interstitial content in IF steel directly contributes to its superior performance in forming operations, making it the material of choice where complex shapes and smooth surfaces are required.

Metallurgical Considerations

The key to achieving interstitial-free characteristics lies in controlling interstitial atoms. Titanium and niobium are commonly used as stabilizers because they form stable carbides and nitrides, preventing unwanted interactions during cold rolling and stamping.

Additionally, careful annealing and rolling processes help maintain the fully ferritic microstructure. This ensures consistent mechanical properties across large sheets, which is essential for industrial applications where precision and repeatability are critical.

Advantages Beyond Automotive

While IF steel is synonymous with automotive manufacturing, its benefits extend to other industries:

-

Appliances: The smooth finish and formability make it ideal for washing machines, refrigerators, and other appliances with visible steel surfaces.

-

Furniture Manufacturing: Office and household furniture benefit from the material’s ability to take complex shapes without cracking.

-

Packaging and Containers: Steel cans and containers can be manufactured with thinner gauges, saving material and cost while maintaining structural integrity.

Challenges and Considerations

Despite its advantages, IF steel has some limitations:

-

Cost: The addition of stabilizing elements like titanium or niobium increases production costs compared to standard low-carbon steels.

-

Welding Challenges: Its softness can require special welding techniques to avoid burn-through or distortion.

-

Limited Strength: While formable, it cannot match the high tensile strength of advanced high-strength steels, limiting structural applications.

Manufacturers need to carefully balance these factors against the benefits, choosing the right steel grade based on application-specific requirements.

Future Trends in Interstitial Free Steel

Research continues to improve IF steel, focusing on enhancing its mechanical performance while reducing production costs. New processing techniques, such as controlled rolling and advanced annealing cycles, aim to optimize microstructure and surface quality even further.

Additionally, the demand for lightweight vehicles and sustainable manufacturing practices is driving innovation. By combining IF steel with coatings and alloys, engineers can create hybrid solutions that meet modern safety, efficiency, and environmental standards.

Conclusion

Interstitial Free steel represents a significant advancement in material science, particularly in the automotive sector. Its ultra-low carbon and nitrogen content, combined with stabilizing alloying elements, results in a highly formable, soft material that excels in deep-drawing applications. From vehicle body panels to appliances and furniture, this steel grade has transformed manufacturing possibilities, enabling lighter, stronger, and more aesthetically appealing products.

As industries continue to seek materials that combine performance, efficiency, and design flexibility, IF steel is set to remain a critical component in modern manufacturing for decades to come.